Impact Gloves Manufacturer

Impact Gloves Manufacturer (OEM & Wholesale Supplier) 🛡️

When Hands Take Hits, Impact Gloves Matter 💥

In tough environments, it’s not just cuts—it’s sudden knocks, pinches, and repeated strikes that injure hands. That’s why Miraj Enterprises manufactures impact gloves built to protect knuckles and the back of the hand while keeping movement practical for real work.

We support OEM and wholesale buyers with impact glove designs that can be configured for dexterity, grip, and comfort, depending on your industry and hazards.

Where Impact Gloves Are Commonly Used 🏗️

Impact gloves are frequently sourced for:

-

Oil & gas operations

-

Construction and infrastructure

-

Mining and heavy industry

-

Mechanical and industrial maintenance

-

Material handling near pinch points and tools prone to kickback

If you need general-purpose protection (without knuckle guards), see our Work Gloves category.

What Makes a Glove “Impact-Resistant” 🧠

Knuckle & Back-of-Hand Protection (TPR and beyond)

Many impact-resistant designs use raised rubber-like guards (often TPR) placed across knuckles/fingers to reduce injury from common strike zones.

Certification & Ratings (what buyers ask first)

Buyers often ask about ANSI/ISEA 138 impact ratings and how to confirm a glove is truly impact-rated (not just “impact-style”).

OEM Customization That Buyers Actually Request 🎨

Build it for your jobsite & market

Common OEM requests include:

-

Knuckle padding coverage (full vs low-profile)

-

Palm material selection for grip in oily environments

-

Combined protection needs: cut + impact + dexterity

-

Touchscreen fingertips (where relevant)

-

Logo, labels, and packaging for private label

To explore other glove types we manufacture for different industries, visit our Gloves range.

Quality Control ✅

We run bulk consistency checks around:

-

Padding placement & durability

-

Stitching and seam strength

-

Size consistency and fit

-

Pre-shipment inspection

FAQs People Really Ask (from buyers + communities) 🤔

What are impact gloves used for?

Impact gloves are used when workers face knuckle/back-of-hand strikes, pinch points, or impact tools where hand impacts are likely.

How do I know if gloves are truly impact-resistant?

Buyers commonly verify ANSI/ISEA 138 markings/claims and ask for proof beyond marketing text.

What does ANSI/ISEA 138 mean?

It’s a widely referenced standard for impact protection performance on knuckles/fingers; buyers often ask what “Level 1/2/3” implies for jobsite risk.

Are impact gloves too bulky for dexterity?

This is one of the most common pain points—people want impact protection that still lets them handle small parts and tools.

Do you have low-profile / “smallest” impact gloves?

Yes—low-profile designs are frequently requested for better mobility while keeping knuckle guards.

Can impact gloves also be cut-resistant?

Many buyers specifically request cut + impact together, especially for construction and heavy-duty tasks.

Which industries buy impact gloves most?

Common high-demand sectors include construction, oil & gas, mining, and industrial maintenance.

Are impact gloves good for vibration tools?

Buyers often ask about vibration/hand fatigue and whether padding choices help; the right design focus depends on tool type and usage.

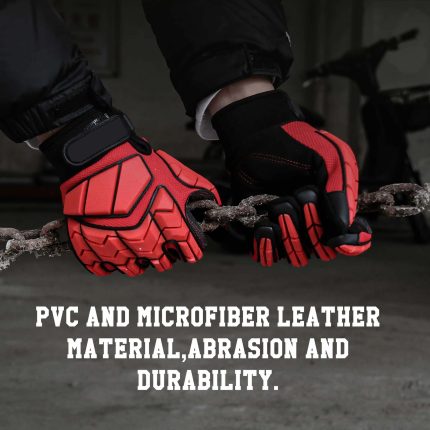

What are impact gloves typically made from?

Questions about materials are extremely common (palm materials, liners, durability choices).

How should we choose sizes for bulk orders?

Sizing/fit is a frequent buyer question; measurement-based sizing is often recommended over guessing S/M/L.

Do you offer samples before bulk production?

Yes, sampling before bulk is a common OEM expectation and reduces buyer risk (especially for padding feel + dexterity).

What is the MOQ for OEM impact gloves?

MOQ varies by materials, padding complexity, and branding requirements (this is one of the most common RFQ questions on B2B platforms).

Can you do private label packaging?

Yes, logo, labels, and retail-ready packaging are standard private-label requests.

What’s the difference between “impact-style” and impact-rated gloves?

Buyers often ask this because many products look similar; verification typically depends on standards/testing evidence.

Request OEM Pricing 🤝

If you’re sourcing from a reliable impact gloves manufacturer for OEM or wholesale supply, we’re ready to assist.

👉 Request a quote to discuss specifications, MOQ, and production timelines.